|

Murphy LS200 Series Liquid Level Switches液位开关应用于洗涤罐系统

LS200, LS200N, LS200NDVOR, L1100 – Liquid level switches

MURPHY LS200系列液位开关专为苛刻的气体压缩机洗涤器应用而设计,具有坚固的设计,仅在液位上升时跳闸。有了电动和气动两种型号,仪器可以直接拧入容器,也可以通过外部浮子室安装。镀镍阀体提供了增强的腐蚀保护,而304不锈钢浮子在0.55比重和更重的液体中工作。其他功能包括:Designed for harsh gas compressor scrubber applications, the LS200 Series Liquid Level Switches feature a robust design that trips on rising liquid level only. With both electric and pneumatic models available, the instruments screw directly into the vessel or can be mounted via an external float chamber. The nickel-plated body provides enhanced corrosion protection while the 304 stainless steel float operates in 0.55 specific gravity and heavier fluids. Additional features include:

- Rated for 2000 psi (13.8 MPa) [138 bar] working pressure

额定工作压力2000磅/平方英寸(13.8兆帕)[138巴]

- Listed for Class I, Div. 1, Grp. C & D locations

列为I类1类。C&D位置

- Canadian registered

加拿大注册

- Stainless steel models available for corrosive atmospheres

适用于腐蚀性环境的不锈钢型号

MURPHY LS200 Series Liquid Level Switches PDF Catalog

Murphy Series LS200, LS200N and LS200NDVOR Liquid Level Switches

The LS200 Series replaces the Murphy Series L1200 Liquid Level Switches. The MSLS (Scrubber Level System) replaces the LS200 high-level shut-down switch with the MLS-020 magnetic level switch.

LS200 、LS200N 、LS200NDVOR 系列及L1100 液位开关产品特点:

. 适用于原气天然气压缩机洗涤罐

. 304不锈钢浮球,适用范围:比重0.5或更重液体

. LS200 系列产品的额定工作环境压力为2000 psi (13.8 MPa)[138 bar]

. 可选型号:电动或气动

. 通过减少活动部件等改良的设计,为产品提供更敏感的开关动作和更高的可靠性。

. 所有型号均可直接安装在容器上,也可通过外部浮球箱安装。

. 镀镍外壳提供更好的防腐蚀保护

. 改进的浮球螺纹连接使得接口更可靠

. 符合I级、1区、C&D组区域标准

. 加拿大注册号:OF1476.2

LS200, LS200N, LS200NDVOR Series and L1100 Liquid Level Switches

LS200 Liquid Level Switches with 2” NPT mounting are float activated to operate an electrical SPDT snap switch (optional DPDT on some models) for alarm or shutdown of an engine or electric motor. The LS200 connects directly into the vessel wall and can be used with a weld collar (P/N 15050375) or Murphy

external float chamber. L1100 models (1-1/2” NPT) are also available.

LS200 Series Liquid Level Switches pdf catalog

|

|

|

MLS-020 Liquid Level Switch (15700839)

|

L1100 Electric Level Switch (15700045) |

L1200 Electric Float Switch (15700060) |

|

|

|

LS200 Liquid Level Switch (15700759)

|

LS200SS Liquid Level Switch; Stainless (15700764) |

LS200N Pneumatic Liquid Level Switch (15700757) |

|

|

|

LS200NDVO Pneumatic Level Switch (15700756)

|

LS200NDVOR Pneumatic Level Switch (15700761) |

|

MLS-020 Liquid Level Switch (15700839)

L1100 Electric Level Switch (15700045)

L1200 Electric Float Switch (15700060)

LS200 Liquid Level Switch (15700759)

LS200SS Liquid Level Switch; Stainless (15700764)

LS200N Pneumatic Liquid Level Switch (15700757)

LS200NDVO Pneumatic Level Switch (15700756)

LS200NDVOR Pneumatic Level Switch (15700761)

LS200, L1100

LS200系列液位开关通过2” NPT螺纹进行安装,通过浮球高度变化驱动单刀单掷开关(可选双刀双掷开关),从而出发报警或停止发动机、电机的运转。LS200可直接安装到容器壁上,也可通过焊接套筒(产品号:15050375)或摩菲公司外部浮球箱与容器相连。

L1100型的安装螺纹为1-1/2” NPT。

LS200NDVOR

LS200NDVOR是一个浮球控制、气体驱动排泄阀或类似装置的设备。

LS200NDVOR的安装螺纹为2” NPT,输出气动开关量,驱动摩菲公司气动排泄阀或其他气动装置。

驱动装置的气体要求是清洁的,干燥的,符合仪表气源要求的空气或其他气体介质。一套LS200NDVOR包括一个压力调节过滤阀、一个气动调节器,同时为了延长系统的寿命并确保系统无故障运行,产品标配中还包括一个摩菲公司的20BPG型压力表。LS200NDVOR气动液位开关(包括:气动调节器、压力调节过滤阀和压力表)

LS200NDVO

带有速动气动调节器(DVO),不带压力调节过滤阀的气动液位开关适用于自带过滤器可以提供符合仪表气源要求的空气或其他气体介质的系统。带气动调节器的LS200NDVO气动液位开关

LS200N

不带DVO和压力调节过滤阀的气动液位开关

LS200N气动液位开关

压力容器安装:LS200 、LS200N 和L1100

所有型号

. 阀体: 镀镍钢; 可选316 不锈钢( 符合NACE 标准MR-01-75, 可直接在H2S环境中工作)

. 浮球:304 不锈钢, 适用范围: 比重0.5 或更重液体

. 额定压力:2000 psi(13.8 MPa)[138 bar](仅限LS200)

. O型圈:Viton橡胶

LS200

. 连接:2” NPT

. 额定温度:-20-300°F(-29-149°C)

. 电路连接: 标准单刀双掷( 配置请参考“ 电路连接” 部分)

. 电线:18 AWG x 36 in. (1.0 mm2 x 916 mm)

LS200NDVOR

. 连接:2” NPT

. DVO:三路“常闭”;手动调节器,所有连接均为1/8” NPT(最小所需压力30 psig)

. 压力调节过滤阀:

. 压力调节:0-75 psig(0-517 kPa)[0-5.17 bar]

. 最大输入压力:300 psig(2.07 MPa)[20.7 bar]

LS200NDVO

. 连接:2” NPT

. DVO:三路“常闭”;手动调节器,所有连接均为1/8” NPT

LS200N

. 连接:2” NPT

. 排气阀:2路“常闭”; 1/16in.(2mm)喷孔、Viton橡胶内座;进口:1/8” NPT;出口:3/8” NPT

L1100

. 连接:1-1/2” NPT

. 额定压力:1500 psig(10.3 MPa)[103.2 bar]

. 浮球:BUOYGLAS., 适用范围:比重0.5或更重液体;可选不锈钢浮球,适用0.65比重液体

. 电路连接: 单刀双掷(SPDT) 开关

装运重量及尺寸

所有型号:6磅(10 盎司、3公斤); 尺寸:14 x 5 x 3-1/2 in.(356 x 127 x 89 mm)

第15章4160-20-00 60-62-40 -15

Features:

Designed for harsh gas compressor scrubber applications

304 stainless steel float operates in 0.5 specific gravity and heavier fluids

LS200 series rated for 2000 psi (13.8 MPa) [138 bar] working pressure

Electric and pneumatic models available

Improved design provides better snap action and dependability with reduced number of moving parts

All models screw directly into the vessel or can be mounted via external float chamber

Nickel plated body to provide enhanced corrosion protection

Improved float connection thread design provides a more secure connection

Listed for Class I, Div. 1, Grp. C & D locations

Canadian Registration Number OF1476.2

Designed for harsh gas compressor scrubber applications, the LS200 Series Liquid Level Switches feature a robust design that trips on rising liquid level only. With both electric and pneumatic models available, the instruments screw directly into the vessel or can be mounted via an external float chamber. The nickel-plated body provides enhanced corrosion protection while the 304 stainless steel float operates in 0.55 specific gravity and heavier fluids. Additional features include:

- Rated for 2000 psi (13.8 MPa) [138 bar] working pressure

- Listed for Class I, Div. 1, Grp. C & D locations

- Canadian registered

- Stainless steel models available for corrosive atmospheres

The LS200 Series replaces the Murphy Series L1200 Liquid Level Switches. The MSLS (Scrubber Level System) replaces the LS200 high-level shut-down switch with the MLS-020 magnetic level switch.

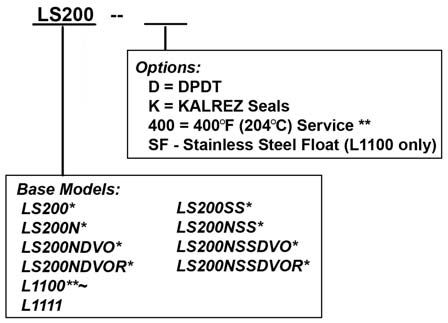

Models

LS200 Liquid Level Switches with 2 in. NPT mounting are float activated to operate an electrical SPDT snap-switch (optional DPDT on some models) for alarm or shutdown of an engine or electric motor. The LS200 connects directly into the vessel wall and can be used with a Murphy weld collar or Murphy external float chamber.

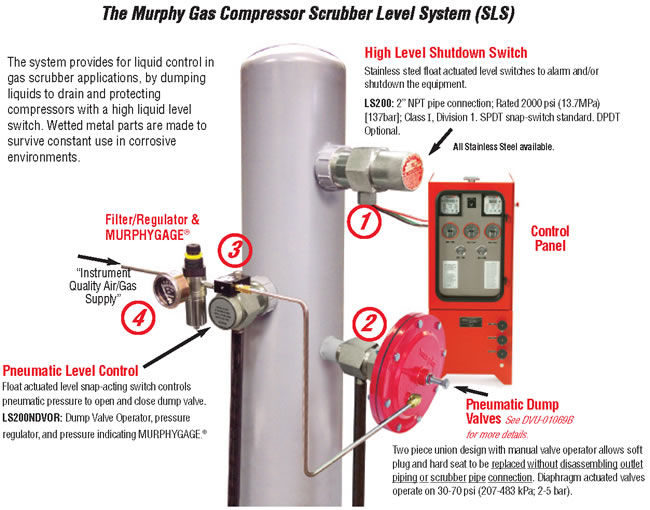

LS200NDVOR is a float-activated, pneumatic-vent level device used to operate DVU Series dump valves or similar devices. It provides a 2 in. NPT mounting with a pneumatic output for interfacing with pneumatic devices such as the Murphy pneumatic dump valve or other pneumatic instrumentation.

LS200NDVO is the Dump Valve Operator (DVO) without the pressure regulator for those applications where the system provides a filter regulator for instrument-quality air or gas as the control medium.

LS200N is the pneumatic level switch without the DVO or filter regulator. Please note: pneumatic media devices require clean, dry, instrument-quality air or gas.

All Models

- Body: Nickel-plated; optional 316 stainless steel

- Float: 304 stainless steel

- Pressure Rating: 2000psig (13.8 MPa) [138 bar]

- Canadian Registration Numbers (issued by ABSA):

- LS200: 0F01476.2

- L1200, L1200N and L1100 Series: 0F01476.0

LS200

- O-ring: Viton

- Process Connection: 2” NPT

- Temperature Rating: -20° to 300°F (-29° to 149°C)

- Electrical: SPDT std.

- Wiring: 18 AWG x 36 in. (1.0 mm2 x 916 mm)

LS200NDVOR

- Process Connection: 2” NPT

- DVO Valve: 3-way N.C. w/manual operator, all connections 1/8” NPT (minimum 30 psig required)

- Filter/Pressure Regulator Set:

- Regulator: 0 to 75 psig (0 to 517 kPa) [0 to 5.17 bar] range

- Maximum Input Pressure: 300 psig (2.07 MPa) [20.7 bar]

LS200NDVO

- Process Connection: 2” NPT

- DVO Valve: 3-way N.C. w/manual operator, all connections 1/8” NPT

LS200N

- Process Connection: 2” NPT

- Vent Valve: 2-way N.C. w/ 1/16 in. (2 mm) orifice and Viton seat; Inlet: 1/8” NPT; Outlet: 3/8” NPT

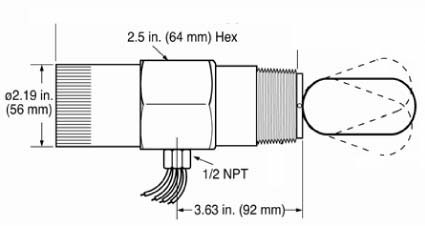

Dimensions - LS200

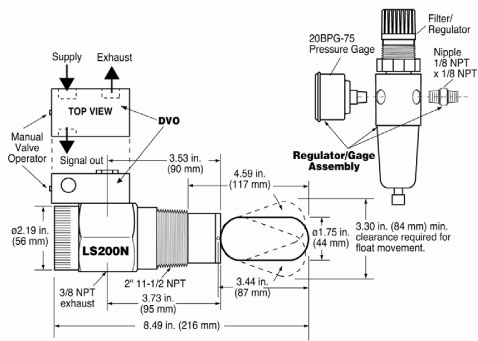

LS200N, LS200NDVO, and LS200NDVOR with Dump Valve Operator, Pressure Regulator & Gage

How to Order your Level Switch:

- For more information about this product, you can download the related literature here:

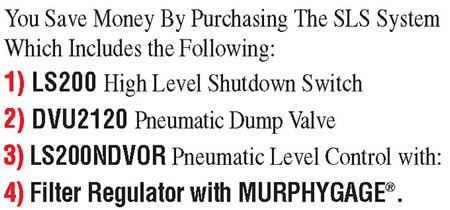

Scrubber Level System - Sales Bulletin (04005; revision date: 09/2017) Scrubber Level System - Sales Bulletin (04005; revision date: 09/2017)

Sales Bulletin (0600009; revision date – 09/2015) Sales Bulletin (0600009; revision date – 09/2015)

Installation Instructions (00-02-0671; revision date - 04/2016) Installation Instructions (00-02-0671; revision date - 04/2016)

LS200

Process connection: 2” NPT

Temperature rating: -20 to 300°F (-29 to 149°C)

Electrical: SPDT std. (see “Electrical” section for

configuration/rating.

Wiring: 18 AWG x 36 in. (1.0 mm2 x 916 mm)

LS200NDVOR

Process connection: 2” NPT DVO valve: 3 way N.C. w/manual operator, all connections 1/8” NPT (minimum 30 psig required) Filter/pressure regulator set: Regulator: 0 to 75 psig (0 to 517 kPa) [0 to 5.17 bar] range Maximum input pressure: 300 psig (2.07 MPa)

[20.7 bar]

LS200NDVO

Process connection: 2” NPT DVO valve: 3 way N.C. w/manual operator; all connections 1/8” NPT

LS200 N

Process connection: 2” NPT Vent valve: 2 way N.C. w/ 1/16in. (2mm) orifice and Viton seat; Inlet: 1/8” NPT; outlet 3/8” NPT

L1100

Process connection: 1-1/2” NPT Pressure rating: 1500 psig (10.3 MPa) [103.2 bar] Float: BUOYGLAS. operates to 0.5 specific gravity; Optional stainless steel to operate in 0.65 specific gravity Electrical: SPDT switch

SLS.System.–.Automatic.Level.Control.for.Gas.Scrubber.Applications

|