|

美国Murphy摩菲LM500油位维持计 自动补油器

Murphy LM500-TF Oil Level Maintainer 润滑油自动补充装置LM500/LM500-TF

Murphy LM500 Series maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running-oil-level

LM500 / LM500-TF | FW Murphy Production Controls

LM500 / LM500-TF | Murphy by Enovation Controls

Murphy LM500-TF机油油位保持器包括一个测试功能,通过一次按下测试按钮即可确认浮子和开关均正常工作。LM500系列保持发动机、泵或压缩机的曲轴箱油位。调整到正确的运行油位后,它将在使用时补充机油。如果供油中断且设备继续用油,低液位开关将报警和/或关闭设备。Murphy LM500-TF Oil Level Maintainer includes a test feature that confirms both the float and switch are operating correctly with a single press of the test button. The LM500 series maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running-oil-level, it will replenish oil as it is used. The low-level switch will alarm and/or shutdown the equipment if supply oil is lost and the equipment continues to use oil.

产品名称:Murphy LM500-TF Oil Level Maintainer LM500油位维持计 PDF CATALOG

技术资料下载

LM500适用于给任何发动机补充机油,它还自带有三线,弹簧式开关。C形式(三线)触点允许控制器/信号器按照一个闭环系统接线,形成一个可靠的故障感应线路。参照LM500系列关于应用程序数据的流量图表。

摩菲 LM500-TF 润滑油补充装置包括一个测试功能(一个单压测试按钮),用于确认浮球和开关可以正确操作。LM500系列维护发动机、水泵或压缩机的曲轴箱机油位, 当机油位在低位时会自动补充。如果供应的机油已用完和设备在持续的消耗机油,低位开关将会报警和/或停止外部设备。

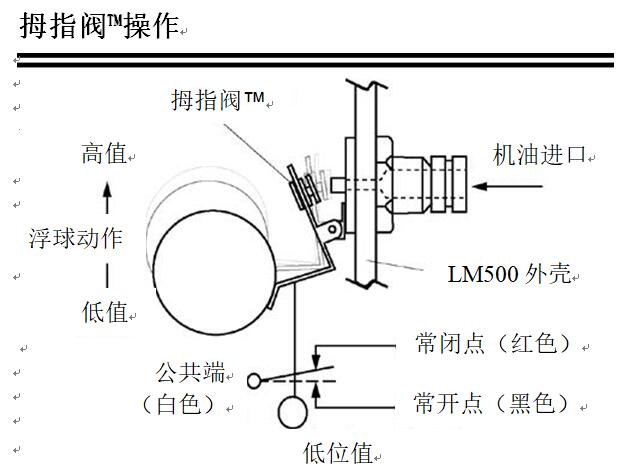

随着曲轴箱的机油位降,LM500浮球也下降并打开拇指阀。它将允许机油从外部油箱通过LM500流入到曲轴箱里。当曲轴箱的机油位达到合适的位置,LM500浮球上升引起拇指阀关闭(防止更多的机油流入到曲轴箱里)。

这个简单和独特的拇指阀不会堵塞,提供一个无泄露的密封。

如果外部油箱的油用完且机油位持续下降,低位开关将报警或停止设备。

产品特性:

测试功能(TF选项):可对浮球及开关的性能进行测试

可采用直接安装方式(DM选项)

低液位报警采用3线制输出信号(可用常开或常闭)

较LM2000系列有更大的玻璃视窗

视窗采用内部密封较之前的边缘密封可靠

简单的安装方式

全长度的高度调整插槽

可选ATEX防爆认证

不锈钢浮球

连接口规格

3个连接口都是 3/4 NPTF

更大的蛙眼视窗

方便检查的绿色条带

曲轴箱平衡通风孔连接: 1/2 NPTF(顶部)。

入口连接: 1/2 NPTF可移动筛网(侧面)。

插座连接:

2 x 3/4 NPTF(侧面)

1 x 3/4 NPTF(底部)

Thumb-Valve?材料: Viton。

快动开关: SPDT等级10 A,125 VAC; 0.5 A,125 VDC; 10 A,30 VDC。

导线: 18 AWG x 14英寸±2英寸(355毫米)长。

导线管连接: 1/2英寸的导线管(母头,顶部)。

外壳: 压铸铝

镜头: 透明的“青蛙眼”不染色,抗冲击,耐高温聚碳酸酯; 紫外线和热稳定。

拨盘: 高可见度白色背景,带有稳定的绿色带,用于正常水平指示。

最大入口压力: 9.50 psi / 25英尺油(扬压)。

最高外壳压力: 15 psi(103 kPa)。

最大差动: 运转和停止之间为2英寸(51毫米)。

最高环境温度: 250°F(121°C)。

浮法: 304不锈钢

流速: 有关应用数据,请参阅LM500系列流速表。

尺寸: 整体高6-9 / 16英寸x深6-3 / 16英寸x深3-1 / 2。

有关确切尺寸,请参阅文档“ 00-02-0729 LM500安装说明”。

LM500 / LM500-TF装运尺寸: 9.5(W)x 7.5(D)x 11 in。(H)(241.3(W)x 190(D)x 279.4 mm(H))。

LM500 / LM500-TF运输重量: 3磅。 13.44盎司(1.74千克)

说明

曲轴箱平衡通风口连接: 1/2 NPTF (顶部)

进口连接: 1/2 NPTF 移动筛 (旁边)

出口连接:

2 x 3/4 NPTF (旁边)

1 x 3/4 NPTF (底部)

拇指阀? 材料: 氟橡胶

弹簧开关: 单刀双掷开关容量10 A, 125 VAC; 0.5 A, 125 VDC; 10 A, 30 VDC

端子类型: 18 AWG x 14 英寸. ± 2 英寸. (355 mm) 长度

导管连接: 1/2 英寸导管 (母头, 顶部)

外壳材料: 压铸铝

刻度盘: 带绿色标志的高可见度的白色背景,绿色标志用于指示正常液位水平。

最大的进口压力: 9.50 psi/25 ft. oil (最顶部压力)

最大的外壳压力: 15 psi (103 kPa)

最大差异: 2 .英寸 (51 mm) 在运行和停止之间

最大的外界温度: 250°F (121°C)

浮球: 304 不锈钢

流率: 参照LM500系列关于应用程序数据的流量图表

尺寸: 整壳 6-9/16 英寸. (H) x 6-3/16英寸. (W) x 3-1/2 英寸. (D)

LM500/LM500-TF 包装尺寸: 9.5 (W) x 7.5 (D) x 11 英寸. (H) (241.3 (W) x 190 (D) x 279.4 mm (H))

LM500/LM500-TF 装船重量: 3 lbs. 13.44 oz (1.74 kg)

规格性能参数 Specifications

Crankcase Balance Vent Connection: 1/2 NPTF (top).

Inlet Connection: 1/2 NPTF removable screen (side).

Outlet Connection:

2 x 3/4 NPTF (side)

1 x 3/4 NPTF (bottom)

Thumb-Valve Material: Viton.

Snap-switch: SPDT rating 10 A, 125 VAC; 0.5 A, 125 VDC; 10 A, 30 VDC.

Wire leads: 18 AWG x 14 in. ± 2 in. (355 mm) length.

Conduit Connection: 1/2 inch conduit (female, top).

Case: Die cast aluminum

Lens: Clear “Frog Eye” non-staining, high impact, high temperature polycarbonate; UV and heat stabilized.

Dial: High visibility white background with solid green band for normal level indication.

Maximum Inlet Pressure: 9.50 psi/25 ft. oil (head pressure).

Maximum Case Pressure: 15 psi (103 kPa).

Maximum Differential: 2 in. (51 mm) between running and stopped.

Maximum Ambient Temperature: 250°F (121°C).

Float: 304 Stainless Steel

Flow Rates: Refer to LM500 Series Flow Rates chart for application data.

Dimensions: Overall 6-9/16 inch tall x 6-3/16 inch deep x 3-1/2 deep.

For exact dimensions, refer to document “00-02-0729 LM500 Installation Instructions”.

LM500/LM500-TF Shipping Dimensions: 9.5 x 7.5 x 11 in. (241.3 x 190 x 279.4 mm).

LM500/LM500-TF Shipping Weight: 3 lbs. 13.44 oz (1.74 kg)

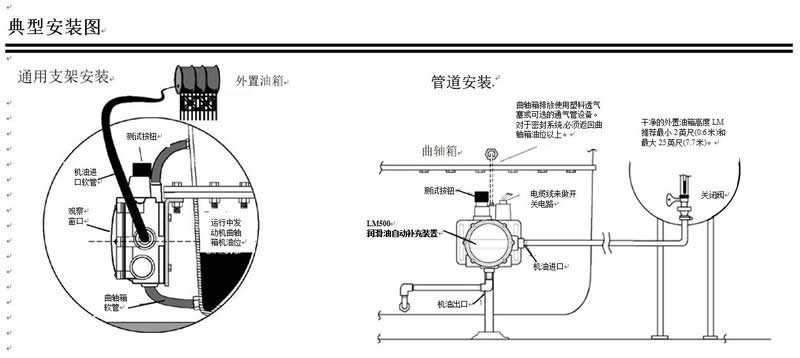

Typical Installations

Murphy LM500-TF Oil Level Maintainer includes a test feature that confirms both the float and switch are operating correctly with a single press of the test button. The LM500 series maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running-oil-level, it will replenish oil as it is used. The low-level switch will alarm and/or shutdown the equipment if supply oil is lost and the equipment continues to use oil. The LM500-TF maintains oil level on any size engine. It also supports installations that require a 3-wire, snap-action switch. The form C (3-wire) contact allows a controller/annunciator to be wired as a closed-loop system, resulting in a reliable fault-sensitive circuit.

As crankcase oil level drops, the LM500-TF float also drops and opens the Thumb-Valve. This allows oil to flow from the supply tank, through the LM500-TF, and into the crankcase. When proper level is achieved in the crankcase, the LM500-TF float rises, causing the Thumb-Valve to close off further oil flow. The simple and unique Thumb-Valve is non-clogging and provides a positive, leak-free seal.

FEATURES:

- Simple installation

- Automatically maintains lube level

- Low level, 3-wire, snap-action switch

- Positive sealing Thumb-Valve

- Eliminates under/overfill due to “human error”

- See oil level and condition without shutting down

- Test Feature (TF) allows test of float and switch

PRODUCT SPECIFICATIONS:

- Part No.: LM500-TF

- Crankcase Balance Vent Connection: 1/2 NPTF (top)

- Inlet Connection: 1/2 NPTF removable screen (side)

- Outlet Connection:2 x 3/4 NPTF (side) 1 x 3/4 NPTF (bottom)

- Thumb-Valve Material: Viton

- Snap-switch: SPDT rating 10 A, 125 VAC; 0.5 A, 125 VDC; 10 A, 30 VDC

- Wire leads: 18 AWG x 14 in. ± 2 in. (355 mm) length

- Conduit Connection: 1/2 inch conduit (female, top)

- Case: Die cast aluminum

- Lens: Clear “Frog Eye” non-staining, high impact, high temperature polycarbonate; UV and heat stabilized

- Dial: High visibility white background with solid green band for normal level indication

- Maximum Inlet Pressure: 9.50 psi/25 ft. oil (head pressure)

- Maximum Case Pressure: 15 psi (103 kPa)

- Maximum Differential: 2 in. (51 mm) between running and stopped

- Maximum Ambient Temperature: 250°F (121°C)

- Float: 304 Stainless Steel

- Flow Rates: Refer to image #4

- Dimensions: Overall 6-9/16 inch tall x 6-3/16 inch deep x 3-1/2 deep

- Shipping Dimensions: 9.5 x 7.5 x 11 in. (241.3 x 190 x 279.4 mm)

- Shipping Weight: 3 lbs. 13.44 oz (1.74 kg)

Engine Fluid Level Switches and Maintainers

Murphy fluid level products offer a wide variety of instruments for the monitoring and automatic maintaining of engine oil, coolant and fuel levels. We also offer fluid level switches and control valves for gas compressor scrubbers, and for monitoring tank or marine bilge levels.

Murphy Lube Level Maintainer with Test Feature - LM500-TF

Murphy Lube Level Maintainer with Test Feature - LM500-TF

Murphy LM500

LM500, LM500TF

Oil level maintainer with sightglass, low level snap-switch and test facility.

Murphy LM500 Level Maintainers

Murphy LM500 Series Level Maintainer

The Murphy LM500 Series maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running-oil-level, it will replenish oil as it is used.

LM500 (15700835)LEVEL MAINTAINER

LM500-TF-KP (15700855) LEVEL MAINTAINER (TEST FEATURE)

LM500-TF-PM (15700843) LEVEL MAINTAINER (TEST FEATURE, PIPE MOUNT)

LM500-UB (15700842) LEVEL MAINTAINER (UNIVERSAL BRACKET)

LM500-PM (15700841) LEVEL MAINTAINER (PIPE MOUNT)

LM500-TF (15700836) LEVEL MAINTAINER (TEST FEATURE)

LM500-TF-UB (15700844) LEVEL MAINTAINER (TEST FEATURE, UNIVERSAL BRACKET)

LM500-TF Oil Level Maintainer with Test Feature 15700836

LM500 (15700835) LEVEL MAINTAINER

LM500-PM (15700841) LEVEL MAINTAINER (PIPE MOUNT)

LM500-TF ATEX (15700837) LEVEL MAINTAINER (TEST FEATURE, ATEX CERTIFIED)

LM500-TF-KP (15700855) LEVEL MAINTAINER (TEST FEATURE)

LM500-TF-PM (15700843) LEVEL MAINTAINER (TEST FEATURE, PIPE MOUNT)

LM500-TF (15700836) LEVEL MAINTAINER (TEST FEATURE)

LM500-TF-UB (15700844) LEVEL MAINTAINER (TEST FEATURE, UNIVERSAL BRACKET)

LM500-UB (15700842) LEVEL MAINTAINER (UNIVERSAL BRACKET)

- 如何订货 how to order

Model/Part Number |

Description |

Notes |

| LM500 |

Lube Level Maintainer |

|

| LM500-TF |

Lube Level Maintainer w/ Test Feature |

|

| 15000954 |

Vent Fittings Kit |

one tubing vent; one 1/4 x 1/2 NPT connector |

| 15000355 |

Hose Kit |

one - 1/2 in. (13 mm) I.D. x 3 ft. (914 mm) hose; one - 1 in. (25 mm) I.D. x 3 ft. (914 mm) hose; two - 1/2 in. (13 mm) worm gear clamp; two - 1 in. (25 mm) worm gear clamp; two - 1/2 NPT x 1/2 in. (13 mm) barbed fitting; two - 3/4 NPT x 1 in. (25 mm) barbed fitting |

| 89080801 |

1/2 NPT x 1/2 in. Hose Barbed Fitting |

|

| 89081001 |

3/4 NPT x 1 in. Hose Barbed Fitting |

|

| 15000518 |

Pipe Bracket Kit |

|

| 15000519 |

Universal Flange Kit |

|

| 15000532 |

Bubble Lens Kit |

|

| 15000943 |

Fittings Kit |

one tubing vent; one hose barb, 1/2 NPT to 1/2 Hose; one hose barb, 1” ID hose x 3/4 NPT; one connector, 1/4 x 1/2 NPT |

-

Compliance Documents / Certificates

- CE Declaration of Conformity

LM500和LM500-TF型号油位维持计 自动补油器实物现货照片 LM500和LM500-TF型号油位维持计 自动补油器实物现货照片

|